Intel & ARM Sign Deal To Manufacturer Next-Gen Mobile SOCs Using 18A Process Node

Intel & ARM Sign Deal To Manufacturer Next-Gen Mobile SOCs Using 18A Process Node

Intel & Arm signed a multigeneration agreement that would allow the manufacturing of next-gen mobile SOCs utilizing the 18A process node. The two companies plan to focus on the mobile sector but will expand "into automotive, Internet of Things (IoT), data centers, aerospace, and government applications."

Current and future Arm clients looking to create the next-generation mobile SoCs will find the added Intel 18A process technology to be a huge benefit to delivering next-gen transistor technologies for increased performance and power that Intel is known for along with the company's rich manufacturing footprint that expands through "U.S.- and EU-based capacity."

There is growing demand for computing power driven by the digitization of everything, but until now fabless customers have had limited options for designing around the most advanced mobile technology. Intel’s collaboration with Arm will expand the market opportunity for IFS and open up new options and approaches for any fabless company that wants to access best-in-class CPU IP and the power of an open system foundry with leading-edge process technology.

— Pat Gelsinger, CEO, Intel Corporation

This joint effort is part of Intel's IDM 2.0 strategy, allowing the company to invest in cutting-edge manufacturing capacity globally, especially in crucial U.S. and E.U. expansions "to serve sustained long-term demand for chips."

The new cooperation with Intel and Arm will allow the two companies to reach a "balanced global supply chain for foundry customers" seeking to work with mobile SoC projects based on Arm's CPU cores. Arm partners can access Intel's "open system foundry model," which allows clients to reach levels above "traditional wafer fabrication." This includes areas such as chipsets, packaging, and software.

Arm’s secure, energy-efficient processors are at the heart of hundreds of billions of devices and the planet’s digital experiences. As the demands for compute and efficiency become increasingly complex, our industry must innovate on many new levels. Arm’s collaboration with Intel enables IFS as a critical foundry partner for our customers as we deliver the next generation of world-changing products built on Arm.

— Rene Haas, CEO, Arm

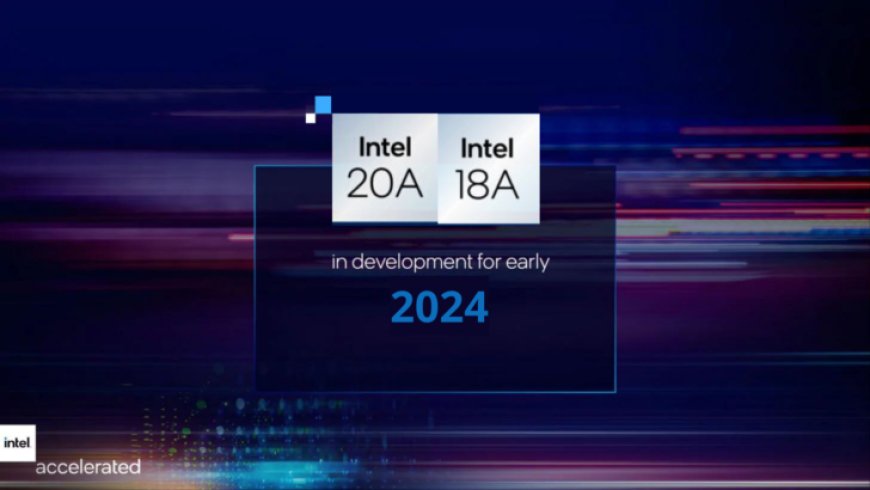

Intel's 18A process node brings a range of improvements over 20A such as a 10% performance per watt increase, Ribbon innovation for design optimization, and line width reduction, to name a few. The development of the process node has already been completed and is expected to be deployed by 2024 before heading for mass production.

It is also reported that Intel has already produced the first test chips on the 20A and 18A process nodes, but it is not mentioned if these chips are internally designed by Intel or for a 3rd party client.

Intel Foundry Services and Arm will begin with design technology co-optimization (DTCO), allowing chip design and process technologies to be optimized for increased performance, power, area, and cost for collaborating partner Arm to utilize their cores that will target the Intel 18A process technology. Intel's 18A delivers PowerVia and RibbonFET to assist with optimized power delivery and gate-all-around (GAA) transistor architecture.

IFS and Arm will start development on the mobile reference design to allow for the demonstration of both companies' software and system expertise for Foundry clients. Arm and IFS will work jointly to increase the optimization on both platforms from software and applications through package and silicon, which will help to leverage Intel's open-system foundry model.

What's Your Reaction?